Overview

The remanufacturing scenario covers the manufacturing process flow, in which used or unusable products are remanufactured to near-new condition. A remanufactured product typically retains its original design and key construction components, only worn and unusable components are replaced or maintained. There are two key remanufacturing variants: Remanufacturing scenario specifics: This scenario applies to both newly manufactured products recognized as defective and products returned by customers. Remanufacturing can also be carried out as a processing service. The customer fills up the product for remanufacturing and receives the remanufactured product.

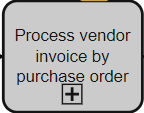

Remanufacturing flowchart

Links to User Guide

- Create production orders for remanufacturing

- Create production stages in remanufacturing scenario

- Release production orders

- Prepare shop floor papers

- Perform recycling

- Complete production stages

- Create production stages in remanufacturing scenario

- Schedule production orders

- Control material availability for production

- Release production orders

- Prepare shop floor papers

- Perform production/kitting

- Complete production stages

- Confirm production

- Consume materials for production